Anti-bending Cable Glands: A Comprehensive Overview

I. Introduction

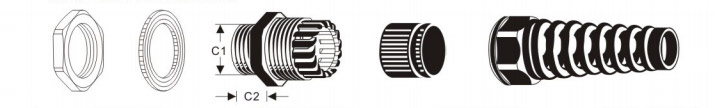

Anti-bending Cable Glands are a crucial component in cable management systems, designed to safeguard cables from damage caused by excessive bending, twisting, and pulling forces. Their unique design and functionality make them essential in various industries where cable integrity and reliable connectivity are of utmost importance.

II.What types of Strain Relief Cable Glands does Chuangda have?

Thread specification: It covers a variety of standards, including PG7 - PG21, M12 - M27, NPT1/4 - NPT3/4 and G1/4 - G3/4. These diversified thread specifications can meet the connection needs of different users in different application scenarios and ensure compatibility with various devices.

Cable adaptation range: It is suitable for cables with a diameter between 3 - 18mm. This range can cover most common cable sizes and provide users with greater flexibility in cable selection and installation.

Color selection: White, black and other custom colors are provided. Diversified color choices can not only meet the personalized needs of different users for appearance, but also play a role in distinguishing and identifying in some specific application scenarios.

II. Product advantages

Stress relief function: The most important function of this Anti-bending cable gland is stress relief. In the Anti-bending cable connection process, it can effectively relieve the tension and stress on the Anti-bendingcable and prevent the cable from being damaged due to long-term stress, thereby prolonging the service life of the Anti-bending cable and ensuring the stability and reliability of electrical connections.

Strong compatibility: Due to its multiple thread specifications and a wide range of cable adaptation, this product can be widely used in cable connections in different industries and different devices. Whether it is in the fields of industrial automation, power systems or communication equipment, it can play a good role in connection and protection...

Material: The main part of the Anti-bending Cable Gland is made of nylon, and the clamping part as well as seals and O-rings are made of nitrile rubber. Cold-resistant, high-temperature-resistant rubber, high-alkali-resistant, chemical-resistant and corrosion-resistant rubber can be customized.

Protection Degree: IP68, It can effectively prevent water and dust. This level of protection can be achieved within the specified bayonet range and by using an O-ring seal to tighten the tightening head. It can adapt to harsh usage environments.

III. Other types

1.Based on Application Environments:

Industrial Grade: These are designed to withstand harsh industrial conditions such as high temperatures, corrosive substances, and heavy mechanical stress. They are commonly used in factories, power plants, and mining operations.

Commercial Grade: Suitable for less extreme but still demanding environments like offices, shopping malls, and data centers. They focus more on providing reliable cable management in a relatively clean and controlled environment.

Outdoor Grade: Built to resist the elements, including UV radiation, rain, and temperature fluctuations. They are used in outdoor lighting systems, telecommunications infrastructure in the field, and solar power installations.

2.Based on Cable Types:

Power Cable Glands: Specifically designed for power cables, they can handle high voltages and currents. They often have thicker insulation and stronger clamping mechanisms to ensure safe power transmission.

Data Cable Glands: Tailored for data cables such as Ethernet cables and fiber optic Anti-bending cables. They focus on maintaining signal integrity and preventing damage to the delicate conductors and insulation used in data transmission.

Control Anti-bending Cable Glands: Used for control cables in automation systems. They need to provide reliable connections while allowing for flexibility in cable movement to accommodate the dynamic nature of control systems.

IV. Materials

a.Body Materials:

Brass: Brass is a popular choice due to its excellent corrosion resistance and good mechanical strength. It can withstand a certain amount of environmental stress and is suitable for a wide range of applications.

Stainless Steel: Stainless steel offers even higher corrosion resistance, especially in highly corrosive environments like marine or chemical processing plants. It is also stronger and more durable, making it ideal for heavy-duty applications.

Plastic (such as Nylon or Polypropylene): Plastic cable glands are lightweight, cost-effective, and offer good electrical insulation. They are commonly used in applications where corrosion resistance is not a major concern and where a more economical solution is required.

b.Sealing Materials:

(Rubber): Rubber seals are widely used for their flexibility and ability to create a tight seal. They can effectively prevent the ingress of water, dust, and other contaminants, ensuring the integrity of the Anti-bendingcable connection.

(Silicone): Silicone seals are known for their excellent temperature resistance. They can maintain their sealing properties over a wide range of temperatures, making them suitable for applications where temperature fluctuations are significant.

V. Advantages

Cable Protection: The primary advantage is the protection of Anti-bendingcables. By preventing excessive bending and twisting, they significantly reduce the risk of damage to the cable's conductors and insulation. This, in turn, extends the cable's lifespan and reduces the need for frequent Anti-bendingcable replacements.

Reliable Connectivity: Ensure a stable and reliable connection between the Anti-bendingcable and the equipment. This is crucial for the proper functioning of electrical and electronic systems, as any interruption in the connection can lead to system failures or malfunctions.

Versatility: Available in various types and sizes to accommodate different Anti-bendingcable diameters and application requirements. This makes them suitable for a wide range of industries and equipment.

Environmental Resistance: Depending on the materials used, they can offer good resistance to environmental factors such as moisture, dust, chemicals, and temperature extremes. This allows them to be used in diverse operating conditions.